#batch consistency in granulation

Explore tagged Tumblr posts

Text

How VJ Instruments' Rapid Mixer Granulator Streamlines the Granulation Process

For pharmaceutical manufacturers and research facilities, it has always been a tightrope walk between getting consistent quality granules while not compromising on efficiency. The granulation process, of course, is critical for tablet manufacturing, often becoming the bottleneck in manufacture pipelines. This is where VJ Instruments' Rapid Mixer Granulator (RMG) comes into play, revolutionizing the approach to pharmaceutical granulation.

Understanding Modern Granulation Challenges

Pharmaceuticals are still being put to great tests in their granulation process:

Poor reproducibility of particle size

Long process times, which have a direct bearing on production time

High energy consumption, with difficult cleaning and maintenance procedures

Variable quality of end products

These challenges are not just about production times but directly affect the final product's quality and uniformity. This highlights the need to choose quality granulation equipment for pharmaceutical industries.

VJ Instruments: Engineering Excellence Meets Practicality

The VJ Instruments' Rapid Mixer Granulator stands out due to its innovative approach to design, overcoming pain points in granulation while introducing new efficiencies into the process.

Advanced Mixing

One of the core parts of the system is the three-zone mixing chamber, which includes:

Primary mixing zone with optimized blade geometry

Secondary zone of high shear for uniform particle size

Tertiary zone of homogenization for uniform distribution

This triple-zone design allows for complete mixing while protecting sensitive materials with delicate handling—a task that traditional equipment rarely accomplishes.

Intelligent Process Control System

The RMG comes equipped with:

Real-time monitoring of critical parameters

Automatic adjustments to mixing speeds

Accurate granulation end-point detection

Data logging to support batch consistency and regulatory compliance

Time-Saving Design Features

Innovative features of the RMG reduce processing times, such as:

Quick-release bowl design for easy and fast cleaning

Tool-less assembly and disassembly

Automated cleaning systems

Smooth and easy product transfer

Performance Metrics That Matter

The VJ Instruments RMG delivers measurable improvements:

40% reduction in granulation time compared to traditional methods

25% reduction in power consumption

99.9% batch-to-batch consistency

60% faster clean down between batches

Quality Assurance Built In

Every aspect of the RMG design focuses on product quality:

GMP-compliant materials

Proven cleaning procedures

Comprehensive documentation package

Control system compliant with 21 CFR Part 11

Practical Applications and Versatility

The system excels in a variety of applications, including:

Wet granulation for immediate-release tablets

Dry granulation for moisture-sensitive formulations

Multi-layer tablet preparation

Formulation processing of modified release formulations

Industry-Specific Adaptations

VJ Instruments offers custom solutions for:

Research and development laboratories

Pilot-scale manufacturing facilities

Full-scale manufacturing operations

Contract manufacturing organizations

ROI and Operational Benefits

Investing in VJ Instruments' RMG means actual savings:

Minimized labor costs through automation

Reduced material waste

Improved product quality

Increased capacity

Reduced maintenance

Sustainability Features

VJ Instruments prioritizes environmental awareness along with operational productivity:

Energy-saving motors and drives

Water-saving cleaning systems

Minimized waste generation

Recyclable component materials

Support and Service Excellence

VJ Instruments provides comprehensive support with:

Installation and commissioning support

Operator training programs

Preventive maintenance schedules

24/7 technical support

Regular software updates

New Equipment Transfer

Acquiring new equipment involves extensive planning. For VJ Instruments, here's what they provide:

Implementation roadmap with detailed analysis

Validation-support documentation

Process transfer assistance

Training materials and resources

Quality assurance protocols

The Future of Pharmaceutical Granulation

Despite changes in the pharmaceutical industry, VJ Instruments’ RMG is designed to face all challenges that the future may bring. Modular designs and easily upgradeable components make this product not only a solution for today but also an investment in tomorrow's manufacturing capabilities.

Need a Change in Your Granulation Process?

How can VJ Instruments' RMG Rapid Mixer Granulator optimize your pharmaceutical manufacturing operations? Contact our Technical Team for a FREE PERSONALIZED CONSULTATION and DEMONSTRATION on how our RMG can meet your specific production needs.

#Rapid Mixer Granulator#pharmaceutical granulation#high-efficiency granulation machine#batch consistency in granulation#VJ Instruments

0 notes

Text

[ID: A close-up of a baguette lined with sliced cucumber and topped with cauliflower coated in a deep red sauce, diced tomato, and a white sauce. End ID]

Sandwich with sesame-gochujang cauliflower and garlic-yoghurt sauce

Inspired by Vietnamese bánh mì thịt, this submarine sandwich pairs fresh vegetables with fried cauliflower coated in a spicy, tangy, savory, and sweet sauce. Toasted sesame oil and the fermented notes of gochujang add depth and complexity to the mildly nutty backdrop of the cauliflower, while the raw garlic in the yoghurt sauce brings the taste profile to a sharp head.

Also consider pairing the gochujang cauliflower with vegetables of your choice in a rice bowl or salad.

Recipe under the cut!

Patreon | Paypal | Venmo

Ingredients:

Serves 4.

For the dish:

4 bánh mì, or 2 freshly baked baguettes halved and cut open

300g cauliflower florets (1/2 a small head)

1/2 cucumber, sliced

2 inches carrot, julienned

1 small roma tomato, diced

Other toppings of choice

Drizzle toasted sesame oil

1 Tbsp toasted sesame seeds

For the batter:

2 Tbsp (15g) all-purpose flour

2 Tbsp (20g) potato starch

1 Tbsp (10g) egg replacer for baking (optional)

Water

For the gochujang sauce:

2 Tbsp gochujang

1 Tbsp gochugaru (Korean red chili flakes)

1 Tbsp granulated sugar

1 Tbsp Korean soy sauce

2 tsp rice vinegar

2 cloves garlic, grated

1 green onion, sliced

Pinch salt

Pinch MSG (optional)

Several cracks ground black pepper

Water

For the yoghurt sauce:

1/4 cup non-dairy yoghurt

1 clove garlic, grated

1 tsp high-fructose corn syrup, or sugar

1/2 tsp rice vinegar

Pinch salt

Instructions:

1. Break cauliflower into smallish florets and wash. Prep vegetables.

2. Mix all gochujang sauce ingredients and use a blender or immersion blender to pulverise the green onion. Add a bit of water as necessary to achieve a slightly runny consistency. Set aside.

3. Mix all yoghurt sauce ingredients and whisk to combine. Set aside.

4. Heat a small pot with several inches of oil to 350 °F (175 °C). Mix all dry batter ingredients in a mixing bowl. Add just enough water to obtain a mixture the consistency of pancake batter. Do not overmix.

5. Coat cauliflower with batter and carefully drop one floret at a time into the oil. You may have to fry them in multiple batches. Fry until lightly golden brown and floating. Set aside onto a paper-towel-lined plate.

6. Increase the heat to bring the oil to 400 °F (200 °C). Fry cauliflower again for 30 seconds until deeply golden brown. Set aside.

If you aren't comfortable deep-frying, you may bake battered cauliflower at 400 °F (200 °C) for 30 minutes, turning over halfway through.

7. Heat a large skillet on medium and cook gochujang sauce, stirring often, until thickened. Add cauliflower and stir to coat. Drizzle in sesame oil and sesame seeds and stir again.

8. Serve immediately with bread, vegetables, and yoghurt sauce.

116 notes

·

View notes

Text

I made a 5 layer black velvet cake to honor Persephone.

This 5 layer black velvet cake is rich, dramatic, and symbolic of Persephone's dual nature as both the goddess of spring and the queen of the underworld.

Ingredients

For the cake layers:

2½ cups all-purpose flour

1½ cups granulated sugar

1 cup buttermilk, room temperature

1 cup unsweetened cocoa powder

1 cup vegetable oil

1½ tsp baking powder

1½ tsp baking soda

1 tsp salt

1 tsp black gel food coloring

2 large eggs, room temperature

1 cup hot brewed coffee (to intensify the chocolate flavor)

1 tbsp vanilla extract

For the black buttercream frosting:

2 cups unsalted butter, room temperature

6 cups powdered sugar

½ cup cocoa powder

2-3 tbsp milk

1-2 tsp black gel food coloring

2 tsp vanilla extract

A pinch of salt

For garnishing:

Fresh pomegranate arils (to represent Persephone’s story)

Blackberries

Cherries

Sliced blood oranges

Raspberries

Small edible rosebuds

Edible gold dust (for a touch of luxury and symbolism)

Instructions

Prepare the cake layers:

Preheat your oven to 350°F (175°C.) Grease and line five 6-inch round cake pans. Alternatively, you can bake in batches if you have fewer pans.

In a large mixing bowl, sift together the flour, cocoa powder, baking powder, baking soda, and salt.

In a separate bowl, combine the sugar, buttermilk, oil, eggs, and vanilla extract, whisking until smooth.

Gradually mix the dry ingredients into the wet ingredients. Once combined, add the hot coffee and black food coloring. Mix until the batter is smooth and the color is evenly distributed.

Divide the batter evenly between the prepared cake pans. Bake for 20-25 minutes, until a toothpick inserted into the center comes out clean.

Let the cakes cool in the pans for 10 minutes, then turn them out onto a wire rack to cool completely.

2. Make the black buttercream frosting:

In a large bowl, beat the butter until smooth and creamy.

Gradually add the powdered sugar, cocoa powder, and salt, beating on low speed until incorporated.

Add the vanilla extract and milk, then increase the speed to medium-high and beat until light and fluffy.

Add the black food coloring and mix until the frosting reaches a dark, rich color. Adjust the milk or sugar as needed to achieve a spreadable consistency.

3. Assemble the cake:

Place the first cake layer on a cake stand or serving plate. Spread a layer of black buttercream on top. Repeat this process with the remaining layers, stacking them neatly.

Once all layers are stacked, apply a thin layer of frosting around the entire cake for a crumb coat. Chill the cake in the fridge for 15-20 minutes to set the crumb coat.

Apply a thicker layer of black buttercream to the entire cake, smoothing the surface as desired. Use a piping bag with a star tip to add decorative swirls and patterns on the top and around the edges.

4. Garnish:

Arrange the pomegranate arils, blackberries, cherries, blood orange, and raspberries on top of the cake to create a lush, dark bouquet.

Place small edible rosebuds between the fruits for a mythical touch.

Lightly dust with edible gold dust for a mystical and otherworldly touch that's reminiscent of Persephone's connection to both the underworld and the beauty of spring.

5. Serve:

Slice the cake and serve to honor Persephone with its rich flavors and symbolic toppings that represent the darkness of winter and the brightness of spring that she brings.

#5 layer black velvet cake#Persephone/Proserpina#goddess of the underworld#Greek and Roman mythology#dark goddess#kitchen witchcraft#food photography#my recipe#witchcraft#witch community#witchblr#witches of Tumblr

12 notes

·

View notes

Text

Pumpkin's Grief Disaster Cookies

yesterday morning my grandpa died, and i wore as close to all-black as i could to work, and i came home and made cookies without a recipe

they're pumpkin walnut! they're tasty! the yield is about 15 per batch, and they take about 15 minutes to bake at 410F. you'll probably want 2 cookie sheets or an extra large one to minimize the long cooking time, but thankfully these are tasty right out of the oven. housemate reviews: "Oh wow! That is so lovely, actually, I would never have guessed you made these without a plan." "It's so good!" they have a cakey, fluffy, chewy bit with a lightly crunchy bottom edge. you can customize the chewiness to crunch ratio a bit (see the picture at the end of the post for reference), but 410 is my personal favorite. i'm going to put the polished recipe before the cut and my actual recipe development process/personal notes below. i want to note that this was inspired by justine_snacks' pumpkin tiramisu cookie recipe, the short for which i saw in the parking lot after getting home from seeing friends, as well as knowing that you really do not need egg in pumpkin recipes after i made her pumpkin bars with chai caramel and cardamom crumble for thanksgiving. (that is the most extra, labor intensive baking recipe i've ever made, and one of my friends described them as the lembas of sweets and is still working on the leftovers. very complex and tasty.) my cookies are less flavorful than i'm sure the tiramisu ones are, but they're wholesome and light and comforting. i do think a pumpkin spice or maple glaze would be really lovely if you wanted them to be sweeter wet ingredients: - 140g unsweetened pumpkin puree - 175g white granulated sugar - 75g dark brown sugar - 1 stick unsalted butter, lightly softened - 1 stick salted butter, lightly softened - 60g unflavored greek yogurt (if the whey has separated since the last time you opened your container, that's fine, just pour it in and then add some of the normal yogurt till you get to 60g) dry ingredients: - approximately 310g white all purpose flour - 30g walnuts (could definitely use more) - 2 teaspoons baking powder fictitious, untried instructions for how a reasonable person might assemble these ingredients: 1. cream butter, sugar and pumpkin puree, until the butter has separated and no large chunks remain; there should still be visible spots of butter and the consistency should be very liquidy

2. lightly fold in yogurt with stand or hand mixer

3. mix together 200g of flour and 2 teaspoons of baking powder; fold together with a spatula, as the dough will be too sticky for your mixer

4. add 30g walnut and another, i dunno, 100-120g of flour; fold till you get a dense, slightly sticky dough (still easily handled) that tastes like it will be good when baked. it should look something like this:

5. chill batter for 15-20 minutes; preheat oven to 410

6. scoop onto a parchment-lined cookie sheet with an ordinary tablespoon or a large cookie scoop if you have one

7. bake for 14-16 minutes (15 was about right for me, but you might check them earlier). a toothpick or fork inserted into the largest part should come out almost entirely clean and the bottom should be a light golden brown

8. chill on a baking sheet before storing; enjoy hot or cold! the cookies will soften over time, so enjoying them the night of or day after baking is best.

anyways, that's it for Fictional Recipe town, see below for how to actually recreate what i did last night

get home around 4pm and decide to use up the pumpkin puree left over from your thanksgiving baking in something. (thanksgiving baking is also the only reason you have both salted and unsalted butter in your fridge)

dump pumpkin on top of two sticks of unsoftened butter, just straight out of the fridge

put frantically back into jar so you can weigh it, like, at least vaguely. the scale showed exactly 140g but it could be lying because this was A Mess

let butter soften; take out your feelings by slapping it real hard with a spatula

sort 200g chana dal and 150g red lentils on a cookie sheet and preheat the oven to 400, which is probably a baking temperature, who knows, whatever!

add sugar

use hand mixer to cream butter, sugar, and pumpkin together till your liquid only has medium-small clumps of butter instead of huge ones. consider that you could continue mixing until it looks fluffy and nice. refuse

thoroughly wash and strain lentils and soak in a large mason jar

lick the batter off the ~wire whips~

add 200 (actually 205) g flour; stir

then add 30g walnuts and decide that since Justine Snacks' recipe had marscapone, yogurt is probably a good idea. dump the separated whey of your greek yogurt into the bowl along with the walnuts, about 8 grams, and then scoop out more yogurt-y yogurt till you get to 60g

add 2tsp baking powder directly to your disaster; stir

decide it needs more flour

at this point, stop noticing the numbers on your food scale

add, uh. 75g flour? fold

then add 50g flour? maybe 25g? 33?? i did not really take enough note

fold

taste batter; decide it is acceptably edible

start cooking lentils; chill batter till you're done cleaning dishes

nevermind, actually change out of your work clothes and put on your headphones and put soap in your dishes and then line sheet with parchment paper and scoop onto the sheet with a tablespoon and your hands. these are fairly large cookies but i at no point measured the pre-cooked weight of any of my dough balls or the post-cooked weight

set in oven and go bake 7 min at 400

wash dishes

take cookies out at 7 minutes; they are wildly overbaked

set a timer for 3 minutes; bake for 3.5 because you got distracted washing dishes

poke with fork; the cookie will completely fall apart in the center; eat the central goop. salmonella from flour the WHOMST and anyway you already ate it raw

stick back in the oven for another 3 minutes

put lentils in a pot with a tsp of turmeric and some canola oil; start boiling

cookies still look sad after 3 minutes but the edges are getting golden! go for another 2

NOW the fork comes out clean. so, nice crispy edge + clean toothpick after 15.5! however that is so long. let's gradually try, um. 410?

bake for 10 minutes; eat one of the first cookies

take out after 10 minutes; they have a noticeable edge now but the center turns to Destroyed Goop again with a fork

turn lentil heat down slightly and take away some of the scum; realize you still failed to get all the sus lentils out of your batch

feed one of the first batch to your housemate

after another 2 minutes the cookies are STILL GOOP

burn your finger putting them back in the oven; rinse with water

bake for another 2 minutes

...nope, that's still underbaked. 4 me.

1 minute later, well, that was 15 minutes, only 30 seconds less than 400. bottom looks darker. weird

decide that you want a cookie that COOKS QUICKLY, so even though the edges will probably darken too fast and they could burn, crank the oven up to 425

start very slowly peeling onions for your dal

wrestle with the by now VERY chill dough; thankfully given the amount of butter it softens well

put your 3 cookies on the sheet; bake for 7 minutes

roughly dice the first 2 onion halves

rinse your hands, check the cookies. wow the edges look much darker than either of the first two batches

set timer for another 3 minutes

dice the next half onion

...the bottoms are burning and the center OOZES goop. the top of these guys just looks. so underbaked

heat 3ish tbsp canola oil in skillet; move lentils to the back burner so you have room to take the cookies out on the stovetop

set timer for another 2 minutes

welp. that is going to burn. switch oven off and chill while you start getting the rest of your dal together. finishing dicing onion, start dicing tomatoes (about 280g of each), after onion is chopped put in 1tsp mustard seeds and 1tsp cumin seeds and a 1" ish piece of cinnamon and a bay leaf and one snapped dry red chili in your hot oil

then very roughly dice some ginger

turn stove down and add said ginger

then stick your onion in and cook for around five minutes

stick cookies back in the chilling oven for, idk, 2 minutes? 5?

finish dicing tomato

add tomato and cook

add a dash of cinnamon, a dash of turmeric, 1tsp cumin power, 1/4 tsp coriander powder, 3/4tsp kashmiri red chili powder, 3/4 tsp cardamom, 1/2 tsp salt and cook with the tomato on low heat

your mom calls to talk about your flight back home for the funeral; talk to her and also your grandma.

feel sad and add lentils slowly to pot with spices

bring to a delicate boil

taste, decide it needs some extra something, and add about a tsp garam masala and stir. also a dash more cinnamon powder

did i mention the cookies are now all chilling on the drying rack? that's happening

heat 1tbsp unsalted butter and then add 1.25tsp mustard seeds; let splutter; temper dal

turn off the heat

try one of the crispy cookies (425 batch) and feed to your other housemate, who likes them despite not seeming like a huge dessert person

decide that fresh-ish as they are this bottom is too crispy and the rest of the cookie is too detached from it, texturallly; go for 410 then next time you do something like this and accept the long cooking time

pour dal over 45g spinach to wilt it; eat and enjoy

make your housemate also eat some dal

do dishes till about 9:30

go to bed with extreme reluctance

plan to share your cookies with IRL friends and also the internet

grief is weird. my grandpa is dead. cookies are good.

here are the 400 at 15.5 minutes (bottom right), 410 at 15 (bottom left), and 425 at 12 + cooling oven time (top), so you can see what i mean about the bottoms being different colors:

there's lots of tumblr posts that are like "cooking is done by feel, baking is a SCIENCE" and i'm sure that's true if you care a lot about quality but. like. baking can be as chaotic as you want it to be. at the end you will, if nothing else, have sweet goop. and at best you'll have taken an awful day and a lot of sadness and made a recipe you're glad to share.

happy Friday!

7 notes

·

View notes

Text

MonkeyGoneToHeaven Cake

MonkeyGoneToHeaven Cake

(Dark Chocolate Banana Cake)

In memory of Kyle.

Ingredients For The Cake:

2 1/2 cups (packed) Dark Brown Sugar 1 1/4 cups Granulated Sugar 2 sticks Salted Butter (softened to room temp) 4 Eggs (room temp) 1 1/2 cups Hershey Special Dark cocoa powder 3 cups unbleached flour 1 Tablespoon + 1 teaspoon Baking Powder 1 1/2 teaspoons Baking Soda 1 teaspoon Salt 2 teaspoons Pure Vanilla Extract 1 cup brewed (drip) strong black coffee (cooled to lukewarm) 5 overripe bananas (the browner the better) mashed -------------------

Ingredients For the Frosting:

2 8oz bricks full-fat Cream Cheese, softened to room temp 2 sticks Salted Butter, softened to room temp 2 teaspoons Pure Vanilla Extract 1 1/4 cups Hershey Special Dark cocoa powder 1 two-pound bag Powdered Confectioner's Sugar 1/4 cup Heavy Whipping Cream --------------------

To Make The Cake:

Preheat Oven at 335 degrees. Grease and flour two 9" cake pans.

Cream the softened butter and the sugars until fluffy.

Add the eggs, one at a time, beating on medium speed between, until batter begins to form. Add the vanilla extract, continue with mixer on 1st speed.

Add the Five Mashed Bananas, beating well on medium speed after adding.

In a separate bowl, sift together the flour, cocoa powder, baking powder, baking soda, and salt.

Begin to add the sifted dry mixture, about a cup at a time, to the wet mixture with the mixer running. Go slow at first, allow a few seconds for it to absorb the dry mix into the batter, as the mixer works it in, before adding the next bit of dry ingredients.

Once the dry ingredients are incorporated, slowly pour in the lukewarm cup of coffee, about 1/4 cup at a time, until it thins the batter down to the right consistency.

Now that everything is in, turn the mixer to highest speed and let it whip for about a minute.

Pour the batter evenly into the two cake pans, and place them on the middle rack of the oven, and bake until the tops are just "solid" and spring back ever-so slightly at the light press of a finger, approximately 46 minutes, at 335 degrees. Keep an eye on them, they might overflow a small amount, which is no great tragedy,

Remove and cool in pan for about an hour. Invert with a cooling rack on top of the cake pan, and slowly and carefully lift the cake pans free of the cake, which should come easily, if you greased and floured your pans properly.

While the two layers are cooling COMPLETELY, it's time to make the frosting. --------------------------

To Make The Frosting:

Cream together the softened butter and cream cheese. Whip on the highest speed for about two minutes until fluffy. Turn speed back down and add the vanilla extract and the cocoa powder, and beat until combined.

Cut the corner of the bag of Powdered Sugar, and begin to gently shake the sugar into the bowl with the mixer on the slowest speed, adding about half a cup at a time, letting it incorporate before adding the next bit. Continue until the whole bag is used and incorporated.

Now, with the mixer on a medium speed, pour in the Heavy Whipping Cream, a bit at a time, until you get the right consistency and "sheen" to the frosting.

Cover tightly and put in fridge until the cake layers are cooled all the way. --------------------------

Assemble the Cake as you would a normal Layer Cake, with a generous layer of frosting between, atop, and all around. Use the entire batch of frosting. Don't skimp.

At this point you can either fridge it until you're ready to cut, to help "set” the frosting, or just wet a knife and cut it, going for the glamour shots first, of course.

This one's for my buddy who's no longer here. He was the ultimate Pixies fan, among other things...and this dark chocolate banana cake will definitely send your monkey to heaven.

Y’all Enjoy!

ptsd

66 notes

·

View notes

Text

Happy Holidays - Have Some Cookies

I feel like sharing this recipe with everyone since I've gotten really positive feedback on them.

Oatmeal Craisin Cookies

Yes, "craisins" as in "dried cranberries." My partner and I aren't big raisin fans, but we do love craisins. If you're the opposite, you can easily swap them out, obviously.

I don't remember exactly how I cobbled this recipe together, I just know that I used at least two different sources.

Ingredients

1 cup salted butter, softened (you can use unsalted butter, but you may need to up the added salt content) 1 cup dark brown sugar, packed (light brown sugar will also work, but I think the lower molasses content will affect the texture and flavor) 1/2 cup white granulated sugar 2 large eggs 2 tsp vanilla extract 1 tsp ground cinnamon 2 cups old-fashioned oats (I don't recommend steel-cut or quick oats, but you do you) 2 cups (240 g) all-purpose flour (I've not tried this with any other type of flour, nor do I necessarily recommend using any non-glutenous or non-glutenous-like flour, as it will at the very least make the batter much looser than intended) 1 tsp baking soda 1 tsp salt 1 cup craisins

Directions

In separate bowl, whisk together eggs and vanilla extract, then add craisins. Let sit to soften craisins. In mixing bowl (stand mixer is HIGHLY recommended as this dough is very thick), mix butter and sugars. Add egg mixture to mixing bowl and mix. Add the rest of the ingredients and mix. Let dough chill in fridge for at least 30 minutes (this keeps them from spreading too much once in the oven; if you want to chill the dough for more than an hour, I recommend rolling it into balls beforehand as the colder the dough gets, the tougher it is to work with, though you can also take the dough out of the fridge and let it warm up on the counter for 30 minutes before trying to work with it). Preheat oven to 375°F. Roll dough into balls by hand (this helps pack the oats and craisins into the cookies so they're not jutting out all over the place once baked; I use a 1" cookie ball scoop just to keep the sizes more or less consistent, then properly roll them before placing them on a cookie sheet; also I recommend wearing gloves for this part, as the dough is VERY sticky and I can't guarantee your hands won't feel like they're coated in butter for hours afterwards no matter how well you wash them). Bake 10-12 minutes (I usually put them in for 11 minutes or a little over, but the exact time depends on your oven; if the dough balls are straight from the fridge, they may need a bit longer; on the upside, there's so much sugar in these that it doesn't hurt if they get a little dark on the edges!).

Notes:

These come out of the oven VERY SOFT, and you might mistake them for not being done - trust me, they're most likely perfectly done, and any longer will result in an unpleasantly crunchy (if not outright burnt) cookie. If you're really unsure about how long your oven needs to bake these, start off doing small batches and let your "test" batch cool down before trying to move them off the parchment paper. If they're still gooey after 5~10 minutes, add another 30-60 seconds to your baking time, but most likely they'll have firmed up enough to at least pick up without them falling apart on you.

I use these "air bake" cookie sheets, which work wonderfully well for these cookies, plus baking parchment; I've not tried making them on regular baking sheets or without parchment, so cooking times may need to be adjusted for that.

Even with chilling the dough , the cookies do still spread out, so make sure to leave a good amount of space between each ball. This recipe makes quite a lot of cookies (about 69 if using a 1" cookie scoop), so depending on your setup, you'll have to work in batches. I try to get all the dough rolled out into balls before I even start baking them, so it's quick and easy to swap them out. We keep our house on the cooler side, so it's not usually a problem, but if your house (or your kitchen) is on the warmer side, you may want to keep the balls refrigerated while they await their turn in the oven.

Lastly, I highly recommend stacked cooling racks for these. Because of how soft they are fresh out of the oven, I'll slide the parchment paper off the cookie sheets and onto a cooling rack with a finer mesh, then transfer the cookies to the stacked cooling racks once they've firmed up a bit (about 2~3 minutes) leaving the finer mesh rack available for the next batch. The reason why I recommend the stacked racks is that, again, this recipe makes a LOT of cookies, so the stacked racks are a good space-saver! Especially since these take a while to cool down completely at room temp (I've not tried chilling them directly post-bake - I think that might affect the texture), and they do need to be COMPLETELY cooled before they can be packed away (otherwise they warp and smoosh into each other - even when completely cooled, they'll stick to each other a bit, but they come back apart easily enough).

Have fun baking cookies! They may not really be "holiday" cookies, but this recipe is my gift to the internet void, so merry happy and all that jazz~

#recipe#cookies#cookie recipe#oatmeal cookies#oatmeal craisin cookies#oatmeal raisin cookies#recipes#baking#food#tag me if you make these!#I wanna know what other people think#or if I need to specify anything else in my directions

21 notes

·

View notes

Text

White Chocolate Pistachio Brownies with Rose and Cardamom

A prayer for Free Palestine

INGREDIENTS

8 oz (226 g) high quality white chocolate bars, chopped, or chips

3⁄4 cup (168 g) unsalted butter, chopped into small cubes

2 eggs

2 egg yolks

1 1⁄4 cups (250 g) granulated white sugar

1 tablespoon (15 ml) vanilla extract

1 3⁄4 cups (219 g) all-purpose flour, spooned and leveled, or weighed

3⁄4 teaspoon salt

1/2-1 cup of roughly chopped unsalted pistachios

A lot of powdered sugar

Rose Water

3-4 cardamom pods

3 Tbs of whole milk

NOTES:

I scaled the recipe up by about a third to bake them in a 9” round. I found out that they come out better if you make them square according to the recipe as is.

INSTRUCTIONS

1. Preheat the oven to 325 degrees. Lightly grease a 9x9 pan and set aside. (You can also line the pan with parchment paper for easier removal.)

2. Melt the butter and the white chocolate together in a double boiler over medium-low heat. Stir continuously to ensure the white chocolate gets heated evenly. Then remove from the heat.

3. Add the eggs, egg yolks, sugar and vanilla to a large bowl and whisk together until pale and smooth. (You can also use an electric hand mixer on high speed to make it easier.)

4. Pour in the white chocolate mixture and whisk until combined and smooth.

5. Fold the flour and salt into the wet ingredients with a rubber spatula just until combined. Then fold in the pistachios.

6. Pour the white chocolate brownie batter into the prepared pan. Use a mini offset spatula to smooth the batter out.

7. Bake the brownies for 30-35 minutes. Then let the brownies cool completely in the pan on a wire rack.

8. Once cool, use a butter knife to loosen the edges of the brownies from the pan, and turn over to gently release. Cut into 16 squares.

9. Make the rose and cardamom drizzle. Warm the milk in a saucepan and break open the cardamom pods. Simmer them in the milk on very low heat until the flavor has infused. Usually 15 minutes to a half hour. Taste the milk to confirm.

10. Strain out the cardamom pods and let the milk cool to room temperature. Add 1/4 tsp rosewater to the milk (you can add more later if you want a rosier flavor) and begin adding powdered sugar. Add a quarter cup to start and stir until no lumps remain. Continue adding powdered sugar until you get a nice thick drizzle-able consistency. Taste and adjust the rosewater content if necessary.

11. Split the icing into two batches. Add pink food coloring to one and green food coloring to the other.

12. Put each icing into separate sandwich bags/piping bags. Cut a very small hole in the corner and use the bag to pipe the icing. Alternatively, you can just use a fork to do the drizzle. Allow to set.

13. Call your reps and demand a permanent ceasefire in Gaza. Go to protests. Boycott Starbucks, HP, Puma, Sodastream and the other companies that support the violence against Palestinians, found at this link. Do everything you can. Don’t look away.

“When Prophet Ibrahim was thrown into fire by the oppressor of the time, Numrud, a bird took drops of water in her beak and dropped it over the fire.

The other animals laughed: ‘what will your drops of water do for the largest of fires?’

The bird replied: ‘it may make no difference to the flames but when God asks me, ‘my Friend was burning, what did you do’ at least I won’t be ashamed.’

When you speak, when you protest, when you write, remember that.

God’s friends are burning. Let us not be ashamed 🇵🇸”

Taken from @zainab_alavi1 on instagram.

When this is over will you be able to face yourself?

#free palestine#free gaza#from the river to the sea palestine will be free#baking#magical cookery#color magic#cottagecore#witchythings#kitchen witch#witchy#witchcore#cooking#honeycore#white chocolate#brownies#cookies

8 notes

·

View notes

Text

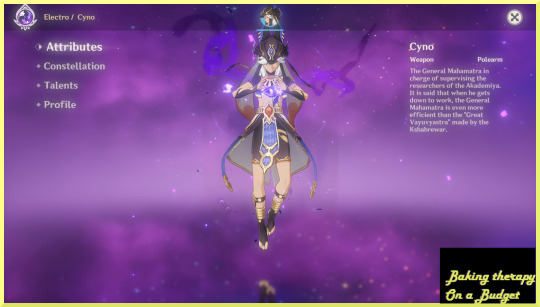

71. Baking therapy on a budget Ft. Genshin Characters: Cyno- Almond Lace Cookies

Hello, every birdy. This recipe is going to be going down in my favorites, and one I am going to make for years to come. But that can only be said when I have almonds in the house.

Cyno is the character that I selected for this recipe. He is a leader of sorts in Sumeru. Like Dehya, one of his favorite foods is nuts. He likes roasted nuts and dried foods. And honestly, in a weird way, this recipe represents that.

The first thing you will want to do is preheat your oven to 325F.

The recipe and the measurements will be in the description down below.

I made some almond butter and I thought it would give me the same constancy if I made my peanut butter cookies. And this was the result.

For the almond butter you will need:

Whole raw almonds

Oil

Food Proccessor

You are going to put 1 cup of almonds into your food processor with approximately 1 tablespoon of vegetable oil. And pulse it for a few minutes, until the natural oils from the almonds come out and it has the same texture as peanut butter. You can add more or less than that if you want. I went with more almonds because it didn’t seem like enough for my family.

For the cookie itself you are going to need:

The almond butter

Egg(s)

Granulated sugar

Baking powder

Baking soda

For every cup of almond butter, you are going to add 1 egg and 1 cup of sugar. Next, you are going to add in your baking powder and baking soda.

Using a cookie scoop or a cereal spoon that measures about 1 teaspoon. Roll each cookie out, in the palm of your hand and repeat. These cookies will be a little bit on the wetter side. But do not worry. They will taste amazing.

Place them 2 inches apart from each other. You do not want them touching because they will spread.

Bake the cookies for about 6-8 minutes. The first batch that I did, I baked them for 8 minutes and they seemed to be a little bit darker than I wanted. So I reduced the time to 6 minutes and they were brown, but not burnt. But when talking about time and baked goods I would just say use your best judgment when it comes to your oven. Every oven is different, and the time may be different for you. Not just talking about these cookies, I am referring to any recipe.

I honestly had not really an opinion about these cookies when I first had the idea for them. Or rather, when my dad and brother came up with the idea. So I made them, and they turned out a lot flatter than I had expected.

BUT… the response to these cookies was overwhelmingly positive. My family really loved them and I brought them in with me for my volunteering, and everyone loved them. They told me that they tasted really good.

As most of you know I use baking as an experimental process so the fact that everyone loved them made me really happy.

I hope that you liked this recipe. Feel free to check it out for yourself. See you in the next post. Thank you.

Pinterest: Here

Recipe::

Ingredients:

Almond butter

1 cup Almonds

1 tablespoon Oil

Almond Butter Cookies

1 cup Almond Butter

1 cup sugar

1 egg

Almond butter is simple to make. I used both a food processor and a high powdered blender, that had a setting for nut butter. And honestly, I preferred the texture and taste of the food processor almond butter. For every cup of almonds that you are going to add about 1 tablespoon of oil. Pulse that for a few minutes, until it has the same consistency of peanut butter.

Preheat your oven to 325F.

For every cup of almond butter you use, you are going to add in 1 egg and 1 cup of sugar. Mix everything together.

Using a teaspoon, you are going to roll out your cookies. They will spread, so do not fill the cookie sheet up.

Bake the cookies for 6-8 minutes.

They have the same consistency as oatmeal lace cookies. They taste amazing. I hope you liked this recipe.

#ts3#simblr#ts3 simblr#baking#baking therapy#recipe#food#Genshin Impact#genshin impact#Cyno#genshin cyno#gi cyno#Almond#Cookies

15 notes

·

View notes

Note

Not an ask, but I made your orange blossom lip balm! While I was at it, I made the face pomatum too. The lip balm seems great, although I couldn't get it to colour at all and it smells more like coconut than anything else. Oh well. The pomatum is, uhm... trickier. It's way more waxy so harder to apply, I can't imagine using it on my face. But I did my elbows and it seemed fine for that. Anyway, thank you for the happy little piratey lunacy!

YESSSSS

So the lip balm:

With regard to color, the only experiment I really tried with that was adding colored mica, and I only did it the once. I've never tried alkanet (because Potential Liver Problems), and while I've considered trying tumeric or similar I've largely shrugged and backburnered that aspect for now. However, you can see a bit in this photo the color differences between the first batch (with the mica) and subsequent:

Figure 1. The first three versions of the lip balm. Bottom left (v.1.1) has the mica, and is slightly more orange-ish than the other two.

With regard to the coconut smell, I've found that I have to be very generous with the orange-blossom water at several stages of cooking in order to keep it present as a scent. While my initial recipe calls for only two "spoonfuls" (which I decided meant a soup spoon of some kind), as of version 3.0, I now specifically use 2+ tablespoons (2 in the original mix, enough extra for the arrowroot, and then... idk, a bit more to Vibe as needed, so it really comes out to more like 3 Tbs). I have notes for 3.1 to up the count to 4-5 Tbs, though we'll see what that does to the consistency.

I also pretty much always make two variants these days: one with coconut oil, and one with sweet almond oil (as described in the original French recipe!). So that might be a fun avenue to try in future.

ON TO THE FACE POMATUM:

I am deeply interested in what your consistency ended up being -- version 1.0 (which I have completed THIS VERY EVENING, and for which I must write up proper notes, because GOSH) is what I'd call a Ye Olde Cold Cream rather than a more modern facial lotion (which tend to be moisturizing without being heavy, as opposed to this, which is easy to use, deeeeefinitely moisturizing, but, uh, will definitely get that moisturizing goodness on anything it touches, goddamn).

Anyway, mine came out buttery af, and seems to still be so, but somewhere between removing it from the water and adding the borax, the fucker got itty bitty granules in it-- just enough to be annoying. Bah. Further research is required.

Figure 2. A smooth(ish) operator pomatum; aka, a sneak peek into later apothecary revelations.

ANYWAY. Thank you @ivoryfeathers for joining in the gay pirate mad scientist experimental fun!

#our flag means death#yes#Y E S#more people having more fun with#experimental archaeology#a pomatum for the lips#aka#stede bonnet's lip balm#the pearl pomatum#(or what WILL be the pearl pomatum anyway)#stede bonnet's theoretical self care extravagances#from#stede bonnet's theoretical library#trifles the amateur history enthusiast strikes again#funky little alchemist with funky little interests#btw if we took out the borax and fixed the granule issue would I call THIS the 'seaman's friend' from that one fic I wrote?#POSSIBLY YES#get yer pirate lube RIGHT HERE FOLKS#WOO

5 notes

·

View notes

Text

Literally my whole brand! <3 ☺️

Anyway, here's a beginner friendly, 3 ingredient, Peanut Butter cookie recipe;

The only ingredients that you'll need for one batch of these cookies are:

[A] 1 cup/255g of Peanut Butter,

[B] 1 cup/200g of Granulated Sugar,

[C] 1 Large Egg!

(These should be room temperature when used! And will probably make you ~around~ 22 or so Cookies.)

=========================================

Note!;

{I unfortunately don't know of any Egg substitutes that work in this recipe for those who can't have Egg, my sincerest apologies. As for what type of Peanut Butter to use, go nuts- (literally, lol.) and use whatever! Though you're probably better off going with a thicker Peanut Butter than a thinner one, I've personally noticed that Jif or Skippy work best. Anyway!}

=========================================

The only equipment that you'll need for this recipe is:

[A] 1 Large Bowl for mixing. (As well as 2 Medium Bowls *if* you're doing the measuring by weight),

[B] 1 Baking Sheet,

[C] 1 Whisk,

[D] 1 Fork,

[E] 1 Measuring Cup, (1 cup)

[F] Baking/Parchment Paper!

=========================================

Note 2!;

{This is a beginner friendly recipe, so you're safe to not be exact! 😁 But in general, baking (while an art) is a little more specific than cooking is, so it's best to stay consistent! Cups, teaspoons, and pinches, are all fine and great! But they *are* less consistent than going by weight!}

=========================================

For the tools, if you don't have a Whisk, then you *can* make do with just the fork or your hands for mixing. If you don't have Baking/Parchment Paper, then you *can* make do with a light coat of Neutral Cooking Oil. (I.e. Canola, Vegetable, Sunflower, Peanut, etc.) And you only *need* the One Measuring Cup, so long as you remember to measure the Granulated Sugar *before* the Peanut Butter.

Also, this is where your batch size may differ, depending on the size of the Baking Sheet you use!

Let's Begin!

Step 1.] Start by preheating your oven to 350°F, or 176.6°C!

Step 1.5] While that's heating up, We're gonna line our Baking Sheet with Parchment/Baking Paper! But here's a tip! If you crumple up the Parchment Paper first, and *then* uncrumple and lay it out over the Baking Sheet, then the new texture from doing that will make it a lot easier to get the Cookies off the tray once they're done! This trick actually works for most baked goods!

- (Alternatively, if you don't have any Parchment Paper, then now is when you would take a little bit of your Neutral Cooking Oil, and thinly coat the side of the Baking Sheet that you're going to put your "Cookie Dough" on!)

Step 2.] Combine the Egg, Sugar, and Peanut Butter into a Large Bowl, and mix well until thoroughly incorporated!

- (You can tell that it's mixed enough when it's all a consistent color and texture- and not super grainy from the sugar! Pretty much just mix until it seems right to you! With other baked goods, you want to be careful about not over-mixing things- with this recipe though, you don't have to be as worried about it!)

Step 3.] Once your "Dough" is mixed together, start taking out a little at a time and rolling it into balls with your hands! The "Cookie-Dough" balls should be roughly an inch thick (if a little less), and then placed on the (now lined or oiled) Baking Sheet about 2-ish inches apart! [If you'd like some suggestions on how to spruce up the mix first, check "Optional Step 3.5!"]

- (Warning! This process can be a bit messy! Also though, keep in mind that these sizes aren't set in stone! If you would like your cookies to be larger or smaller, then you are allowed to do that! Just then keep in mind that the cooking time may increase or decrease as well!)

Optional Step 3.5] Here's where you can get Creative! Or- rather, *a place* where you can get Creative! You can of course skip this Step if you don't want to make any modifications- but here's some suggestions If you do! Maaaaaybe not all at once though-

[♣︎] Throw a couple handfuls of Chocolate-Chips into the mix!

[◆] Add a few splashes of Vanilla Extract! This is what I do most of the time, adding ~about~ 1/2 a teaspoon to a batch this size!

[♠︎] Do a not "unreasonable" few shakes of Cinnamon. Either into the mix, or dusted on top at the end!

[★] Sprinkle a pinch of Coarse Salt on top of the Cookies!

[●] Roll the "Dough-Balls" in a little extra Granulated Sugar before Baking!

- (Of course, these are just suggestions! You can take em, or leave em, or make up your own stuff!)

Step 4.] Once your "Dough" is rolled into evenly spaced balls on the Baking Sheet, take your Fork, and use the back of it to gently press down on the cookies! Do it twice- once vertically, and the second horizontally!

- (This is Crosshatching! You want to gently flatten your Cookies so that they become an actual Cookie Shape, because these ones don't actually do a whole lot of rising and flattening on their own! Don't press down all the way through them though! Only about half-ish way!)

Step 5.] BAKE THE COOKIES! Now that you should have all your Cookies crosshatched, and on the Lined/Oiled Baking Sheet, then- (once your Oven has finished preheating)- put your tray of cookies into the oven! This should take about 8-10 minutes. But it *can* vary sometimes, depending on your Oven!

- (Be sure to keep an eye on them! Once you've made one batch then you'll about know how your Oven handles them, but it's always a good idea to keep an eye on things! Also, something very much to keep note of- these Cookies don't rise, or even really Brown much at all, so they *are* suseptible to Over-Baking. The best way to see if they're done is to visually check if they've set, and by doing the Toothpick Test. (I.e. are the edges just getting golden, and if you stick a toothpick in the thickest part, does it come out clean?)

Step 6.] Assuming that your Cookies are now Baked, you can officially take your tray out of the Oven! Best bet for now is to either put it on your Stovetop, or a couple of Hot-Pads. But even putting it on an Oven Mitt should work! Of course, now it's time to WAIT. My best guesstimate is that it should take *about* 20-ish minutes for them to cool.

- (As sad as it is to have to wait for them cool down, they do turn out better if you do! I'm afraid that's just how the Cookie Crumbles! Hilarious puns aside though, there are a few things you can do here. 1.] If you have a Wire Rack, then after about five or so minutes, you can transfer the Cookies from the Baking Sheet directly to there, which should help cool them down faster. And 2.] If you still have a Batch you need to Bake, and only the one Tray, then again- after five or so minutes, you can transfer the Cookies directly to a plate and have them finish cooling there!)

Step 7.] Enjoy!

======{Helpful Tips!}======

[1.] These Cookies (if kept in an Airtight/Sealed Container after being fully cooled down) can last at Room Temperature for up to Five Days! Though of course, they'll last even longer if kept in the fridge! (I wish I could tell you exactly how much longer, but they're never around long enough for me to find out!)

[2.] If said Airtight/Sealed Container is Freezer Safe, then the Cookies can be Frozen! In which case, they should last for about three-ish months or so! (It takes about an hour, give or take, for the Cookies to thaw from Frozen at Room Temperature.)

[3.] The "Cookie-Dough" can also be Frozen in the Freezer! It'll also last that way for about three months, though I recommend making them into the Crosshatches first. You don't even need to re-thaw them before you bake! Just add an extra couple minutes to the timer!

[4.] If your "Dough" mixture is a little too soft to form into balls, then you can put it in the Fridge for a couple minutes, which *should* help it firm up! Just don't leave it in the Fridge for too long, though, because doing that can dry it out!

What was I talking about again..? Oh yeah! Thanks for liking Peanut Butter!

You're pretty cool, too!

the peanut butter fandom is shockingly small on tumblr. i love peanut butter but it's so hard to find other fans on here

#i am a fish#text post#peanutbuttertextpost#peanutbutterandawesome#peanut butter#long post#recipe#cookies

5K notes

·

View notes

Text

5 Best Capsule Filling Machines in the USA

When it comes to filling capsules for personal use or for manufacturing purposes, the right equipment can make a significant difference in efficiency, quality, and cost-effectiveness. Capsule filling machines are essential for those looking to fill empty capsules with powders, herbs, or other ingredients. In this article, we will cover the 5 best capsule filling machines in the USA, highlighting top models that stand out for their performance, durability, and ease of use. Whether you are a small-scale producer or a home user, this guide will help you choose the perfect machine for your needs.

Why Choose a Capsule Filling Machine?

Capsule filling machines are invaluable for anyone involved in the production of capsules, whether for pharmaceuticals, supplements, or even cosmetics. These machines help you accurately fill empty capsules with a range of powders, granules, or other substances. By automating the process, you can achieve higher productivity, consistency, and reduce the manual effort involved in filling capsules.

Here’s why investing in a capsule filling machine is a smart choice:

Efficiency: Capsule filling machines significantly reduce the time and labor needed to fill capsules compared to manual methods.

Accuracy: The machines provide precise and uniform filling, ensuring consistent dosage for every capsule.

Cost-Effective: Automating the process saves time and money, allowing you to increase output while lowering production costs.

Scalability: Whether you’re a hobbyist or a business owner, capsule filling machines come in various sizes and configurations to suit different production volumes.

Versatility: Many machines offer interchangeable parts to accommodate different capsule sizes and filling materials.

Top 5 Capsule Filling Machines in the USA

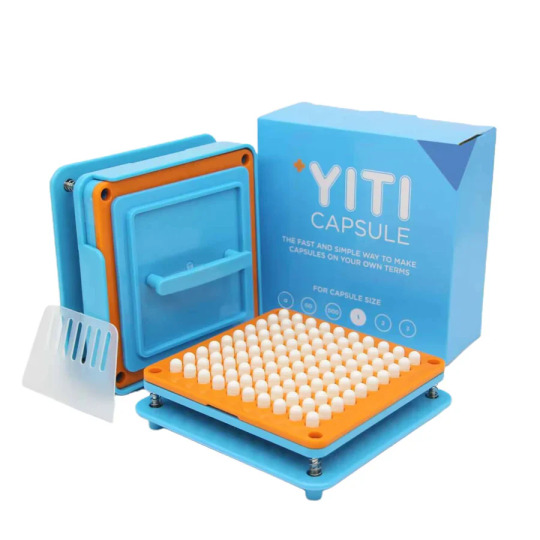

1. YITI Capsule Filling Machine – Size 00 – 400 Holes

Why it’s great: The Capsule Filling Machine - size 00 - 400 Holes is a top contender for users who need a high-capacity machine for filling capsules. With a 400-hole capacity, this machine is perfect for mid to large-scale operations. It is designed for efficiency, making it a great option for both professionals and small businesses looking to streamline their production process.

Key Features:

Size 00 Capsules: Can fill capsules of size 00, which is one of the most commonly used sizes in the supplement industry.

High Capacity: With 400 holes, this machine can fill a large number of capsules in a single cycle, making it ideal for large batches.

Durable Build: Constructed from high-quality materials, this machine is built to withstand frequent use, ensuring long-lasting performance.

Easy to Use: The design allows for easy assembly and operation, making it user-friendly even for beginners.

Manual Operation: This model is manually operated, providing complete control over the filling process.

Ideal For:

Businesses or individuals who need a reliable, high-capacity machine for filling size 00 capsules.

2. YITI Capsule Filling Machine – Size 1 – 100 Holes

Why it’s great: The Capsule Filling Machine size 1 - 100 Holes is a more compact version of the 400-hole model, making it perfect for users who require a smaller output. With 100 holes, this machine provides a more manageable filling capacity while still offering high efficiency and reliability.

Key Features:

Size 1 Capsules: Perfect for filling size 1 capsules, which are commonly used for both supplements and pharmaceuticals.

100-Hole Capacity: The machine can fill up to 100 capsules in one cycle, offering a balance between productivity and ease of use.

User-Friendly: Easy to assemble and operate, even for those new to capsule filling machines.

Durable Construction: Made from high-quality materials, the machine is designed for long-term use.

Manual Operation: Operates manually, giving users full control over the capsule filling process.

Ideal For:

Home users or small-scale businesses that require a compact machine for filling smaller batches of size 1 capsules.

3. Capmation Automatic Capsule Filling Machine

Why it’s great: For those seeking an automatic option, the Capmation Automatic Capsule Filling Machine is an excellent choice. This machine is designed for high-speed filling, allowing users to fill large volumes of capsules quickly and efficiently.

Key Features:

Automatic Operation: Fully automated, which means the machine handles the entire process from capsule filling to closing, making it ideal for larger-scale production.

High Capacity: Can handle a large number of capsules per cycle, significantly reducing production time.

Precision Filling: Ensures precise and uniform filling of capsules, improving consistency and dosage accuracy.

Versatility: Suitable for a wide range of capsule sizes, making it adaptable to different product lines.

User-Friendly Interface: Comes with an intuitive control panel for easy operation and monitoring of the process.

Ideal For:

Medium to large-scale businesses looking for an efficient and high-speed automatic capsule filling machine.

4. CapsuleMatic Manual Capsule Filling Machine

Why it’s great: The CapsuleMatic Manual Capsule Filling Machine is an excellent choice for users who want a simple, manual machine that delivers high-quality results. This compact machine is perfect for smaller production volumes and provides excellent control over the filling process.

Key Features:

Compact Size: Ideal for small operations, the CapsuleMatic is perfect for personal or small-scale commercial use.

Manual Operation: While it requires more effort compared to automatic machines, it provides complete control over the capsule filling process.

High Efficiency: Despite its manual operation, this machine can fill up to 100 capsules per cycle, making it an efficient option for small batches.

Affordable: One of the most cost-effective capsule filling machines on the market.

Ideal For:

Home users, hobbyists, or small businesses looking for an affordable manual option.

5. Acro-Label Automatic Capsule Filling Machine

Why it’s great: The Acro-Label Automatic Capsule Filling Machine is another high-performance machine designed for large-scale production. It offers automated filling and is perfect for those looking to optimize their capsule production process.

Key Features:

Fully Automated: The machine handles all stages of the capsule filling process, from capsule insertion to closing, without the need for manual intervention.

High Productivity: Designed for high-speed operation, this machine can fill thousands of capsules per hour.

Precise Filling: The automatic control ensures precise and consistent filling, improving the overall quality of the finished product.

Built for Durability: Constructed with durable, high-quality materials to ensure a long service life even in high-demand environments.

Easy to Clean: Features a design that makes it easy to clean and maintain, ensuring compliance with safety and hygiene standards.

Ideal For:

Large-scale manufacturers who require a high-speed, fully automated solution for capsule filling.

0 notes

Text

Melt Flow Index Tester to Measure the Melt Volume Rate

Source of Info: https://www.perfectgroupindia.co.in/blog/melt-flow-index-tester-to-measure-the-melt-volume-rate

Introduction

An accurate device to measure the melt volume rate of thermoplastic materials under special conditions is the Melt Flow Index Tester. It is an important equipment for quality control and product development because it helps manufacturers to identify how a polymer will behave during processing. This device calculates the amount of material flowing through a die over a set time by offering valuable data for comparing material levels. It allows consistent product performance and reliable manufacturing and is very accurate and simple to use. For industries searching to improve their testing capabilities with advanced, user-friendly equipment Perfect Group India provides trusted solutions.

Why Use a Melt Flow Index Tester? An instrument used in labs to measure the flow properties of thermoplastic polymers is called a Melt Flow Index Tester. It monitors how quickly molten plastic moves through a die at a given temperature and pressure. Depending on the measurement unit this flow rate is referred to as the Melt Volume Rate (MVR) or Melt Flow Index (MFI).

The test results which show how much material extruded from the instrument in that time, are given in grams per 10 minutes (for MFI) or cubic meters per 10 minutes (for MVR). These results help manufacturers in creating the behavior of the material during actual processing, such as blow molding, extrusion or injection molding.

Why Measuring Melt Volume Rate is Important The Melt Volume Rate of a material is important for these reasons:

Quality Control A Melt Flow Index Tester can be used by businesses to test polymers on a regular basis to make sure the materials meet demands before going into manufacturing. Defects, waste and expensive rework are decreased as a result.

Material Comparison Industries often require to compare various batches or suppliers of polymer materials. Measuring the MVR guarantees reliability across batches which is important for large-scale manufacturing.

Process Optimization By adjusting processing parameters like temperature and pressure based on the flow characteristics, engineers can improve product quality as well as productivity.

Regulatory Compliance International standards (like ASTM D1238 or ISO 1133) must be followed in many industries, especially the packaging and automotive sectors. Reliable data for records and certification is provided by Perfect Group India.

How Does a Melt Flow Index Tester Work? The way a Melt Flow Index Tester works is simple but accurate:

Preparation: A pre weighed amount of thermoplastic granules is loaded into a heated barrel.

Melting: The material is allowed to melt and stabilize at the specified temperature.

Extrusion: A standard load is applied through a piston, pushing the molten polymer through a die.

Measurement: The extruded material is collected over a 10-minute interval and weighed or its volume is measured to calculate the MVR.

Advanced testers offer digital displays, automated cutting mechanisms and load controls to increase accuracy and ease of use.

Industries that Choose on Melt Flow Index Tester The device is used across a variety of industries where plastics play a key role:

Packaging Industry: Guarntee film consistency and uniformity

Automotive: Testing thermoplastics for performance important features

Medical Devices: Quality assurance of polymers for hygienic and durable use

Consumer Goods: Verifying material strength and moldability

Construction: Provide PVC pipes and profiles meet strength and flow specs

No matter the sector, the equipment provides high-quality manufuring with less downtime and better product performance.

Why Choose Perfect Group India for Your Melt Flow Index Tester? At Perfect Group India we understand the important function that testing instruments play in manufacturing success. For this reason we provide accurate, reliable and reasonably priced products that are suited to your industrial requirements.

High Accuracy Our testers are engineered for consistency and accuracy helping your lab meet global standards like ASTM and ISO.

User-Friendly Interface Designed for ease of use our testers come with digital displays, programmable settings and automated features.

After-Sales Support Perfect Group India provides full technical support, calibration services and training to guratee your team gets the best out of your investment.

Competitive Pricing We believe quality doesn’t have to come at a premium. Get industry-leading equipment at affordable rates with Perfect Group India.

Tips for Getting the Most Out of Your Melt Flow Index Tester

Calibrate Regularly: Provide accurate results by following a regular calibration schedule.

Use Consistent Sample Sizes: This reduces variability in results.

Maintain Clean Equipment: Residue buildup can affect flow and measurements.

Train Operators: Skilled users provide more consistent, reliable results.

Conclusion In quality control a Melt Flow Index Tester is an important device for accurately measuring the melt volume rate of thermoplastic materials. In order to maintain manufacturing quality and follow industry standards it helps manufacturers to identify the flow characteristics of polymers. It is used in the polymer, plastic and packaging industries because of its simple functioning and reliable results. This equipment improves the testing processes, increasing productivity and saving time. It is important in material testing labs and is trusted by experts in many different fields. Perfect Group India provides trustworthy options for polymer testing instruments that are accurate and durable.

0 notes

Text

Baking: a (somewhat flexible) Science

I've posted a variation of this one already, at least once. Posting again today to dive into an area that frightens a lot of inexperienced bakers, that being the "flexibility" of any given recipe's proportions when any number of variables are introduced into the equation.

This is a batch of Banana-Chocolate-Chip muffins. It's half again as large, yielded 18 instead of just 12 (the usual). That was purely incidental to my point.

The last few batches of muffins I've baked I have had to modify due to various circumstances, the lack of one ingredient that I was sure I had plenty of, a surplus of eggs but no milk, etc.

The latter of those situations was what started these investigative jaunts: I had two dozen eggs on hand, but no milk. Up until then, I had always added the prescribed amount of milk.

However, that batch I had an extra banana over what I usually have to use, and I didn't realize it but I bought extra large eggs, and I had plenty of 'em.

I thought it logical to make up the amount of liquid with the liquidity of the extra banana and (what ended up being) two extra huge-ass eggs. The eggs on the plus side give extra protein and structure. They make the crumb of the muffins incredibly soft, but still substantial.

The only other adjustment I ended up making was to add about a half-teaspoon extra Baking Powder to get the rise correct.

Using other ingredients as part of the liquid required, and correcting the final outcome with additional BPdr.

This batch today was an intentionally heretical extension of this principle. Although I have plenty of milk on hand, I wanted to test my theory further.

The base recipe for these calls for just one egg per six muffins, and 1/3 cup milk. I intentionally left the milk out, and doubled the eggs and bumped up the Bpdr an extra teaspoon.

I also made a slight adjustment to baking time/temp I'll decribe below.

So the final recipe today was:

2/3 cup salted butter

2 cups granulated sugar

4 large over-ripe bananas

4 extra-large "jumbo" eggs

3 3/4 to 4 cups flour (the Bob's Red Mill Pastry Flour was on sale for cheap at safeway this time)

1 Tablespoon + 1 teaspoon Baking Powder

1 teaspoon cinnamon

1/2 teaspoon nutmeg

3 teaspoons vanilla

1 teaspoon kosher salt

2 cups milk-chocolate chips

Sprinkling Sugar Crystals (approx 1/4 cup per 6 muffins)

The jumbo eggs as well as the extra banana liquid worked perfectly, and it ended up yielding 18 jumbo muffins instead of the usual 12.

When people say baking is a science, I say yes, it is, BUT: where the "baking is magic" people have it over on the lab-coats is learning what ingredients do what, to what degree, and how well does the end product turn out with a bit of creative re-proportioning/substitution.

An added bonus to ingredient switching/enriching is added nutritional value: Protein bumped up, no milk fats. And there is extra added value in "keeping" quality: with extra eggs and the butter, these will stand being out on the counter, under a cake bell, for quite a number of days before they become truly stale or need refrigeration.

And one last aspect of this I wanted to point out: Those carefully-worded procedures that are painstakingly written out aren't ALL carved in stone, either, but there are generally some that you just never stray from if you want CONSISTENT results, the rest can kinda fall in as they can, whichever you reach for next while the mixer's running.

The never-stray category starts off with the one arch rule: start with the butter and sugar. Start with solid or slightly softened butter and granulated sugar. Period. Add in the baking powder and vanilla and salt. Cream that until it begins to give you little peaks as it mixes.

You can add the eggs next, or the bananas, whichever you wish, and end up with adding just the plain flour at the end.

You need a "liquid component", but there are several ways that liquid component can be configured, two of which I've discussed this evening.

And, adding this in here at the end: The usual baking time for these muffins is 23 minutes at 400 degrees. BUT: with these differences in ingredient proportions, at Denmark-trained roomie's suggestion, I backed down on the temp at the end and left them in an extra few mintues. That helps avoid the "Post-Oven Shrinkage" that happens when they're not baked all the way through. So instead of biz as usual, I baked them for 20 minutes at 400, then backed it down to 325, and left them in for 6 more minutes. They turned out like I planned...no shrinkage, no sinking hole in the middle.

And please resist the temptation to jack up the amount of cinnamon and nutmeg: just the barest hint of both is exactly what you're looking for.

Thanks for coming to my TED Talk.

ps: Right now, Groce Out has got the big honkin' 2 lb bag of chocolate chips for $6.99, which is a ridiculously good buy.

8 notes

·

View notes

Text

Best Pharmaceutical Company Delhi

These are the most commonly used oral dosage forms in the pharmaceutical industry due to their stability, ease of administration, and cost-effectiveness.

1. Tablet Manufacturing Process

a. Pre-formulation Studies

Determine drug properties (solubility, stability, flowability, etc.).

Choose suitable excipients.

b. Granulation

Wet Granulation: Binds powders with a liquid to form granules.

Dry Granulation: Used when the drug is moisture-sensitive.

Direct Compression: Suitable for drugs with good flow and compressibility.

c. Compression

Granules are compressed into tablets using a tablet press.

d. Coating (optional)

Film coating or sugar coating for taste masking, stability, or controlled release.

e. Packaging

Blister packs or bottles, labeled and sealed for distribution.

2. Capsule Manufacturing Process

a. Filling

Capsules (usually gelatin-based) are filled with powders, pellets, granules, or liquids.

b. Sealing (for liquid-filled)

Ensures the capsule content remains intact and stable.

c. Polishing & Inspection

Capsules are cleaned and checked for defects.

d. Packaging

Packed similarly to tablets for distribution.

3. Ensuring Quality in Manufacturing

a. GMP Compliance

Following Good Manufacturing Practices (GMP) ensures safety and consistency.

b. In-Process Quality Checks

Weight variation, disintegration, hardness, and friability testing.

c. Stability Studies

Determine shelf-life under various environmental conditions.

d. Microbiological Testing

Ensures the product is free from harmful microorganisms.

4. Supplying Quality Pharma Products

Key Considerations:

Regulatory Compliance: Meet national/international standards (like WHO-GMP, USFDA, EU-GMP).

Proper Documentation: Batch records, CoAs (Certificates of Analysis), MSDS.

Cold Chain Management (if required): For temperature-sensitive products.

Reliable Distribution Network: Ensures timely and safe delivery.

Would you like a sample business profile or catalog content for a pharma company offering tablets and capsules?

0 notes

Text

Wet Granulators Market Set to Reach $1,257.7 Million by 2035

According to recent research by DataString Consulting, the global Wet Granulators Market is projected to grow significantly, reaching $1,257.7 million by 2035 from $523.2 million in 2024. This growth is driven by expanding applications across industries such as pharmaceutical manufacturing, food processing, chemicals, and cosmetics.

Access detailed report insights here - https://datastringconsulting.com/industry-analysis/wet-granulators-market-research-report

Key Market Drivers

Wet granulators are widely adopted in pharmaceutical manufacturing due to their ability to create uniform granules with minimal dust, a factor crucial for drug formulation consistency and bioavailability. High-shear wet granulators are particularly favored in this sector as they help maintain the uniformity of the active pharmaceutical ingredient (API) throughout the granule mix, enhancing drug effectiveness and reducing batch-to-batch variability. Leading pharmaceutical companies like Pfizer and GlaxoSmithKline rely heavily on this technology, reinforcing its strategic value.

In the food industry, wet granulators are essential for processing ingredients to improve digestibility, texture, and shelf life. Oscillating and roller compactor types are commonly used due to their high throughput and ability to preserve the nutritional value of food materials. Companies such as Nestlé and Unilever are prominent adopters, utilizing the equipment across a diverse range of food applications.

Industry Developments and Technological Advancements

The industry has witnessed a strong shift toward more advanced and specialized granulation equipment, particularly in the pharmaceutical and chemical sectors. Innovations in machine engineering and safety are enabling wet granulators to handle hazardous materials and ensure better process control in sensitive production environments.

For example, GEA Group emphasizes cutting-edge machine design to enhance adaptability and efficiency, while Glatt GmbH focuses on solutions for hazardous chemical granulation. Alexanderwerk targets the food industry with highly durable and precise machines, and Frewitt pioneers in cosmetics granulation by incorporating novel design trends.

Regional Outlook

North America is leading the global wet granulator market, thanks to its robust pharmaceutical and biotech ecosystem. The region’s expanding food processing and R&D infrastructure, along with new granulation technologies, are set to drive market growth. Rising awareness around chemical recycling and sustainable material handling is also fueling demand for wet granulators in other industrial segments such as recycling and chemical processing.

Competitive Landscape

The market is highly competitive, particularly in key demand hubs like the U.S., Germany, and the UK. Leading players include:

GEA Group – Focusing on high-efficiency and versatile machine designs.

Glatt GmbH – Delivering solutions suitable for complex chemical environments.

L.B. Bohle, Bosch Packaging Technology, and Gansons Ltd – Offering comprehensive pharmaceutical processing equipment.

Freund Corporation, Kikusui Seisakusho Ltd, Yenchen Machinery, and Nicomac Europe srl – Serving diverse granulation needs across sectors.

These companies are actively investing in R&D, expanding their product lines, and tailoring solutions to meet industry-specific granulation challenges.

Market Segmentation and Opportunities

The Wet Granulators Market is analyzed across multiple segments:

Technology Types: High Shear, Fluid Bed, Rapid Mixer

Applications: Tablet Manufacturing, Capsule Filling, Mixture Blending, Others

End-Use Industries: Pharmaceutical, Food Processing, Chemical, and Other Industrial Sectors

This segmentation spans over 20 countries, providing a detailed view of local and global opportunities for manufacturers and investors alike.

About DataString Consulting

DataString Consulting specializes in strategy formulation and market expansion advisory. With over 30 years of combined experience, their team delivers tailored strategies for Total Addressable Market (TAM) expansion, revenue diversification, and competitive intelligence. Their integrated market research solutions help companies reduce time-to-market and tap into high-growth segments across over 15 industries and 60 sub-industries.

For a more detailed analysis, visit: https://datastringconsulting.com/industry-analysis/wet-granulators-market-research-report

0 notes

Text

What Sets Premium Ferro Alloy Suppliers Apart in Delivering Ferro Titanium Alloys!

In today’s fast-paced industrial environment, quality and reliability aren't just important — they’re essential. For sectors like steel manufacturing, aerospace, shipbuilding, and defense, the performance of end products depends heavily on the materials used. One such critical input is Ferro Titanium Alloys, widely used for their powerful deoxidizing and grain refining properties in steelmaking.

But not all suppliers are equal. What separates premium suppliers from the rest isn’t just access to raw materials — it's a combination of quality control, technical know-how, supply reliability, and deep industry alignment.

1. Commitment to Quality and Purity

Leading suppliers prioritize high-purity ferro titanium, which is crucial in critical industries like aerospace and high-performance steel. The difference between a standard-grade and a high-grade alloy can impact everything from metal strength to weldability and corrosion resistance.